We are the only official distributor in Thailand.

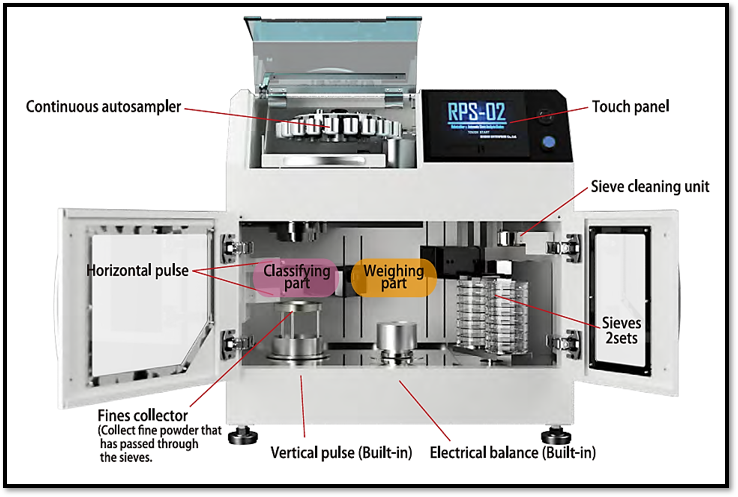

The Robot Sifter RPS-02 is a continuous sieving particle size distribution analyzer that automates everything from sample loading to sieving, weighing, calculations, and sieve cleaning. It can fully measure up to 20 samples. It uses an ultrasonic sieving principle, which reduces friction between the sample and the sieve, allowing for sieving without damaging particles compared to vibration or low-tap sieving methods. Measurement results are displayed on the operation panel and printed to various printers. The

RPS series, a long-selling product with a proven track record, is a great choice for streamlining your process management, quality inspection, and more.

Robot Shifter (RPS-02)

Specification

| Item | Specification |

| Sieve dimensions | φ75 dedicated sieve |

| External dimensions | 700W x 560D x 660H mm |

| Weight | Approximately 90kg |

| Power supply | AC100~240V (50/60Hz) 1.5kW |

| Number of sieve stages | 8 levels (optional 10 levels) |

| Opening range | 5600μm to 20μm |

| Number of sample cups | 20 piece |

| Capacity | 17 ml |

| Sound intensity/frequency | 0 to 99 steps / 40 to 99Hz |

| Operating temperature range | 5℃ to 40℃ |

| Operating humidity range | 20% to 85% (no static electricity or condensation on the sieve) |

| External Communications | USB (2.0) x 1 (for ESC/PR compatible printers) |

| RS232C x 1 (for PCs and serial printers) | |

| Control connector x 1 (for external dust collector control) | |

| Touch panel | Display size: 7-inch widescreen Display color: 16 million colors Display resolution: 800 x 480 |

| Built-in electronic balance | Maximum weighing capacity: 2,200 g (reading limit 0.01 g) Calibration: 2 kg |

Features

| Continuous automatic measurement of up to 20 points, including sieve cleaning | The system automatically measures sample weight, sieving, calculations, data printing, and sieve mesh cleaning, and can measure up to 20 samples continuously. |

| Multi-product measurement possible | Two types of sieves can be set in the device. By changing the mesh size of the set, different types of samples can be measured at the same time. |

| More efficient screening | The effect of mechanical pulses is that the sieve mesh is less likely to clog than with low tap or electric vibrating screens, and sieving time can be reduced. |

| Low noise | It is quieter than low-tap and electric vibrating sieves. |

| Measurements can be performed without destroying the sample | The sample vibrates vertically during measurement, reducing friction between the sample and the sieve mesh, preventing sample destruction and slowing mesh wear. |

| Suppresses static electricity and prevents sample aggregation | By changing the frequency of the sound waves and adjusting the rise and fall times of the sound waves, it is possible to control the sample so that it does not become charged. |

| Prevent data tampering | Users can be assigned to each person in charge, and operation logs for each user are recorded on the device itself. Also, to prevent measurement data from being tampered with, the device does not have a function for editing data from the device itself. The data management PC software can also be optionally changed to DI-compatible software. |

| Free power supply | The input voltage to the device is compatible with AC100 to 240V. |

| Going online | Online measurement is possible by combining the device with an automatic sampling device, automatic transport device, automatic fractionator and recovery device. |